Stabilization

If the floor of the building subsides or cracks appear in the plinth, the soil conditions are likely to have changed below the structure. Groundtek stabilisation solution is a carefully controlled process, in which the geopolymer is injected directly below the subsided floor slab or foundation. Geopolymer fills the voids below the floor structure and immediately supports the structure.

Geopolymer can also be injected into the soil to anticipate, for example, if it’s known that the structure is on unstable soil and possible to subside in the future.

The repair work is always done as non-disruptively as possible. For example, roads are stabilised, if necessary, one lane at a time, so the traffic can go on almost as normal during the repair work. Sunken floor or road surface is stabilized without breaking the supporting structures.

1. Site visit

Our professional teams find out the soil conditions and the cause of subsidence. At the same time the location of the heating cables are checked and the right geopolymers for the project are chosen.

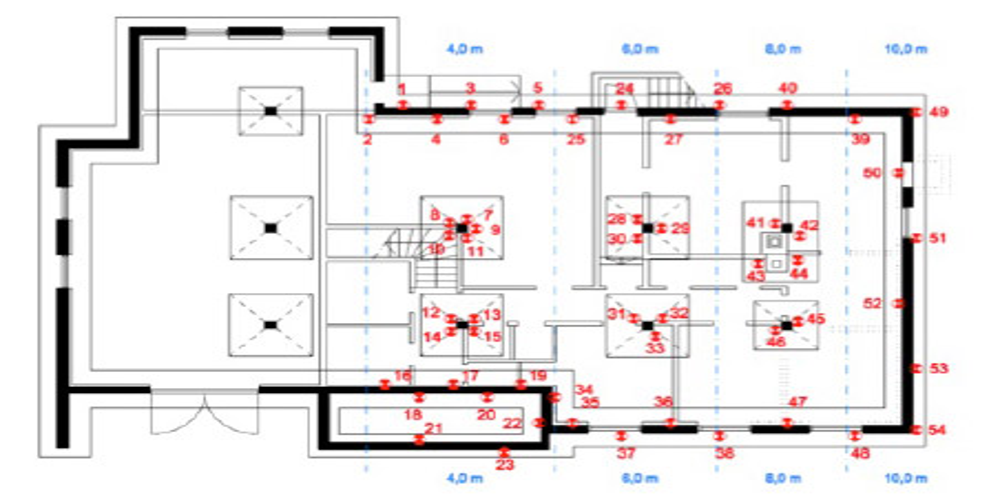

2. Drilling and installation of the injection tubes

Small holes, about 6-12mm in diameter, are drilled through the subsided floor slab or foundation at regular intervals. The injection tubes are then installed in these holes. There is no need to break floors or structures, since the injection holes are drilled in the seams between the tiles. When the injection is done, the holes are filled and sealed in a clean way, so the repairs will not leave any distracting marks.

3. The injection and stabilization

Geopolymer is injected into the soil in liquid form, allowing it to penetrate in a controlled way into all the voids throughout the slab before it becomes gelatinous, and finally solidified. During the repair process, geopolymer binds the loose soil from the area, and thus constitutes a revised support structure. Geopolymer hardens to its required strength in about 15 minutes, after which the treated soil is able again to carry the required loads.

4. The ground will be improved quickly and cost-effectively

The injection process is monitored by laser, which indicates when the soil has reached the desired bearing capacity. The geopolymer that is injected in the soil hardens in about 15 minutes, and the desired bearing capacity of the structure is reached.

5. Benefits of ground improvement

- check The ground can be improved and stabilised quickly and non-disruptively

- check In smaller projects the ground and the soil can be improved and stabilised in a few hours

- check If necessary, you can inject geopolymer on a small, enclosed area

- check The geopolymers that Groundtek use are safe and proven, don’t dissolve in water or give extra load to the surrounding soil and ground.

analytics Steps/Survey

INTERESTED IN OUR SERVICES OR WANT TO GET A PRICE ESTIMATION?

If you want more information about Groundtek and our services, or if you are wondering if our solutions could be the right solution for your object, fill out the contact form and one of our experts will be in contact with you.

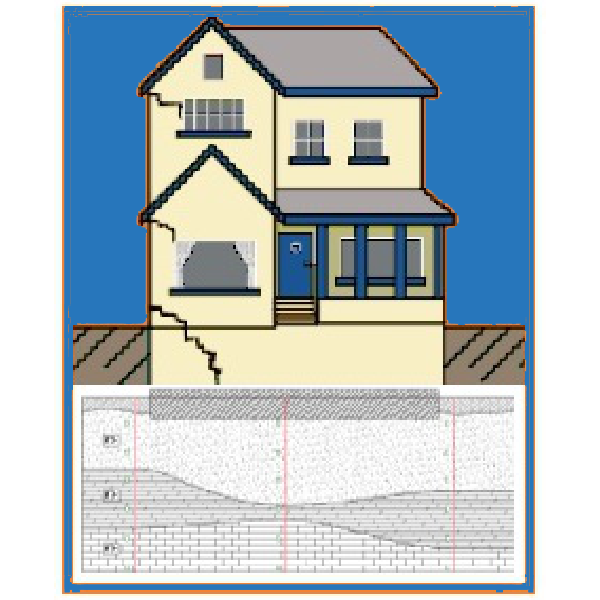

Identifying Subsidence

Subsidence is not without warning signs. Some of the most common include:

- check Cracks in walls

- check Sinking floors

- check Windows and doors sticking

- check Noticeable leaning of property

- check Extension moving away from property

The major sign of subsidence is cracks in walls. Cracks caused by subsidence are normally of a diagonal nature and will suddenly appear in plaster work inside the building and on brickwork outside.

They will usually be thicker than fine hairline cracks, which may be caused by natural movement of a structure, and tend to be wider at the top.

Not all cracks are due to subsidence – fine, hairline cracks are usually nothing to worry about. Subsidence cracks to be wider than a ten pence piece.

Clear Signs

Floors can drop. It’s quite clear to spot this – take a look at the skirting around the floor. If you find gaps, cracks or uneven surfaces your property is likely affected.

You can also look for possible signs of subsidence around weak points in the building, such as doors and windows. Doors and windows can stick or fail to open and close properly due to the building moving from its original foundations.

Building extensions can help detect whether subsidence is a problem. Subsidence cracks are common at points where an extension meets the main buildings, indicating that the extension is pulling away from the main structure and that an intervention may be required.

We can inject our geo-polymer material beneath an extension to stabilise it and prevent further movement, and in some cases also lift it back into place.

Treatment

The principle of our solution involves injecting one of our expanding geo-polymer materials under your property. The material is pumped into the soils as a liquid and expands under the ground.

As the geo-polymer expands it fills the voids in the soils, forces out any water and compacts the soil – this results in a solid stable base under your property’s foundations or floor.

As the material expands in the ground it will follow the path of least resistance until it cannot migrate any further. At this point, the expansive force of the material begins to push up onto the foundations of the property.

We can see when this happens using our laser monitors, which pick up 0.25mm of movement above the injection point.

If we are stabilising the ground we will stop the process at this injection point and move on to the next. We inject at points at around 1.5m apart to ensure the material is equally spread under the problem area of your property.

If lifting the floor, we continue injecting material at the injection point until the floor is lifted to the required level.

The material we use does not degrade — it is a permanent solution comparable to concrete. The process of introducing our geo-polymer to the affected area is faster and cleaner for all types of subsidence.

Cement grouting requires heavy machinery and your property becomes a full worksite. The same applies to screw pillars and underpinning. They all require the excavation of foundation soil. With Geobear, we simply drill small holes and inject our material. Using geo-polymer as a solution to subsidence is the most convenient method and in most cases the preferred option. Other methods, such as underpinning delivered by traditional building contractors, are becoming dated as modern technology evolves.

Slub lifting, Airport Landside

Slub lifting, Airport Landside

The one of the runway slabs at National Airport is subsided. The slab…

STRENGTHENING OF THE FOUNDATION OF A HISTORICAL BUILDING

STRENGTHENING OF THE FOUNDATION OF A HI…

The administrative center of the Belarusian Orthodox Church, which is…