Views 2096

The choice of the correct drilling method is one of the most important decisions and can directly affect the results of the engineering project.

Geotechnology engineers often indicate the use of deep drilling for a better evaluation of the state of the grounds before the start of complex construction projects.

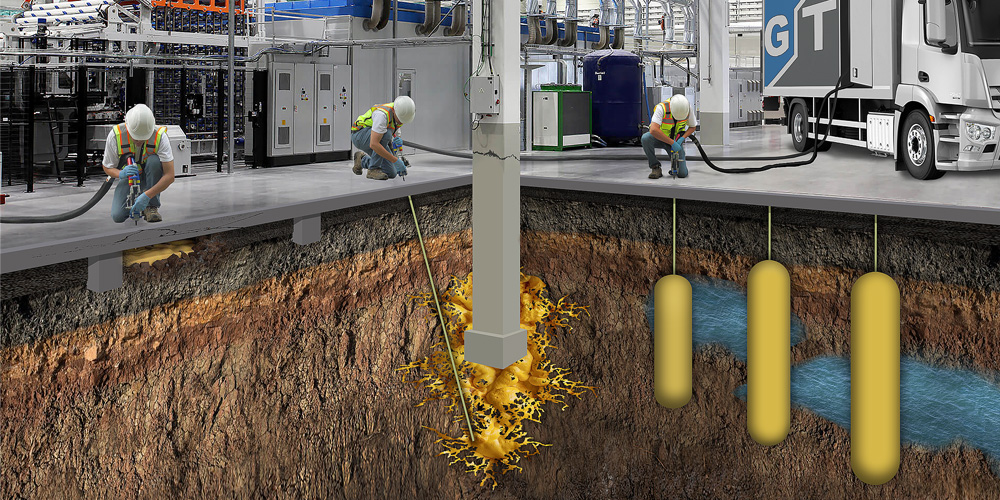

When deeper wells or high-quality soil samples are required, especially in complex geological conditions, ultrasound drilling can be an ideal solution. Ultrasonic drilling uses high-frequency resonant technology, which uses a direct drill tip, penetrating into most of the soil formations, including cobblestones, rock layers and boulders. Such drilling can be carried out in almost all types of soils: from gravel and garbage, to soft sandstone, limestone or weathered basalt.

The high frequency of vibration leads to the fact that a very thin layer of soil particles or rock, directly surrounding the drill column and the tip, loses the structure and temporarily behaves like a liquid powder or pasta.When removing the "suction" bora and vibration allow the soil or breed to reform.

Although initially the technology was developed to accelerate the process of drilling oil wells, it also possessed an outstanding ability to obtain an accurate picture of the continuous core sample from almost any material, even from boulders and rocks.

Possessing an extremely high dive speed, it is able to extract high-quality, intact samples with minimal exposure to the surrounding ground.

Potted core samples of soil inform and help choose the best reclamation solutions

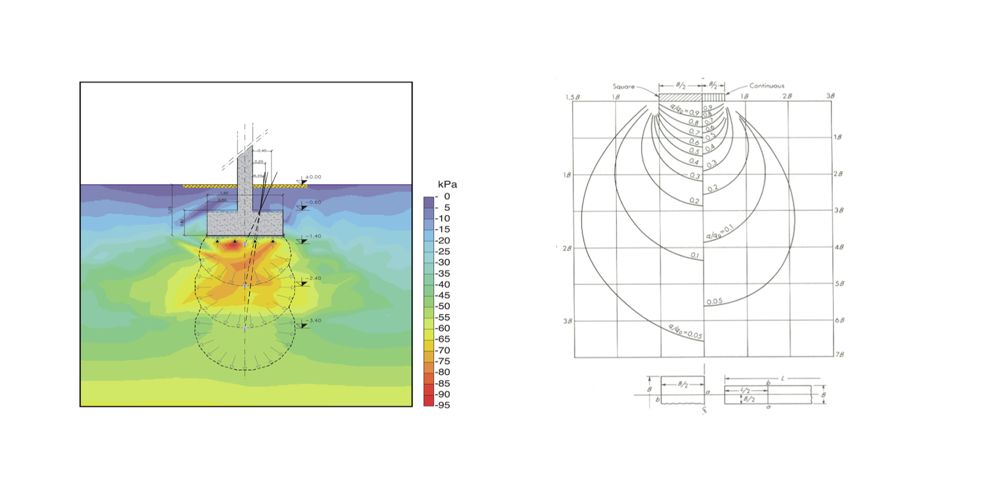

In many cases, deep samples of soil can help better inform about the current state of the base soil.For example, in practice Граундтек England, there was a case when the above-ground railway track on the facility on loading and transporting coal showed signs of uneven precipitation in just four years after construction.

Ultrasonic drilling was used to extract samples that could be analyzed to identify weak soil layers at the base under the railway, where standard sensing methods would simply suffer fiasco due to the obstruction of the probe.

Using samples collected at a depth of 10 m under the web, a suitable solution was found, which helped improve the density of the soil and the carrying ability in weak layers under the rails, while avoiding the damage to the neighboring coal layers.

Innovative technique solves insoluble problems

Ultrasound drilling also played a key role in Australia under the project Граундтек to restore the mine barrel.An abandoned mine barrel, located under the parking lot of the Motel in the regional new South Wales, collapsed, and began to form emptiness, which led to a serious session, touched on both the parking lot and the motel building.

Technically and physically complex project recovery has already been unsuccessful attempting earlier before the contractor Граундтек was attracted.To solve the problem, a mine tamponation method was used for 30 m under water, then clogging and sealing the shaft barrel.

The ultrasound drilling rig was complementary, allowing the team of specialists to successfully restore the site.During a carefully prepared project, the drilling rig was used to install three 76 mm steel housings to a depth of 60 m to provide access to a temporary plug, which allowed technical experts to implement the necessary tampon-made solution for sealing a mine shaft with materials Граундтек.

This unique approach allowed the company to solve an extremely difficult task, which was previously considered intractable.

0 сomments

Post your comment