Views 1804

Some findings and simple criteria for the applicability of Grandtek technologies

The use of injections of polymer resins to seal the soil and restoration of structures made a revolution in how managers of operational services and buildings leaders think about restoration and repair. Thanks to the economic efficiency and innovation in the field of injection technologies, the viability of buildings and structures is "grows significantly." The use of geopolymers covers various areas of economic and social activities, such as the rise of the carriageway, sealing of sewer and joints, filtration barriers. Plotin, stabilization of marine shafts and restructuring of foundations Buildings. The question is when the polymer resin makes sense as a rehabilitation solution?

As you can imagine, this question is filled with "tonna" variables, but we will try our best to determine typical possibilities and questions that you must ask yourself during the search for a solution.

1) Is the situation maintainable by injection of polymer?

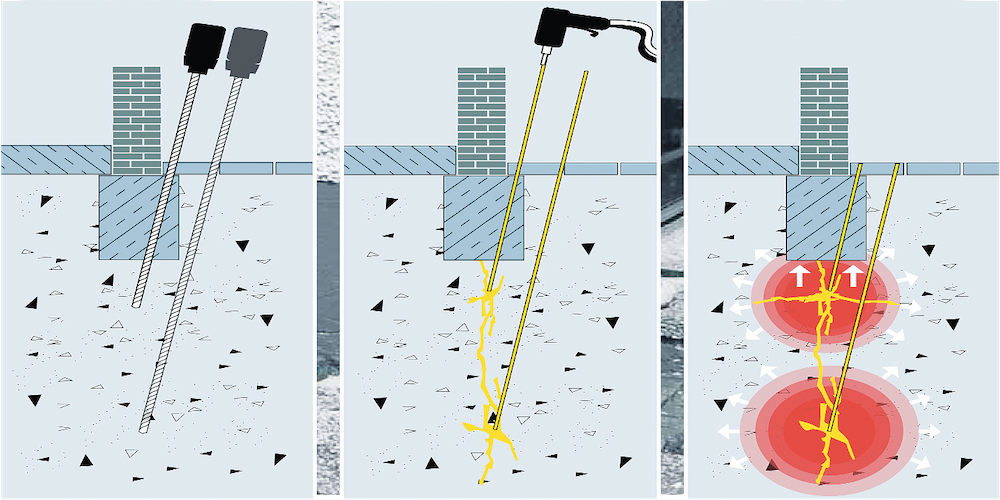

The first thing to consider in connection with this issue is: "Is this question related to the grounds of the construction?" First of all, the injection of polyurethane is used to fill emptiness, whether it is large emptiness, where there is no soil, or emptiness that exist between unconsolidated base particles. The polymer is rapidly expanding, therefore, as soon as the voids are filled, the polymer then compresses and compacts soil, increasing their carrying ability. So if your problem is caused by weak or weakening grounds, the polymer resin can be an excellent solution.

2) What is the condition of the structure being recovered and what are your goals?

Although we obviously think that the injection of polyurethane is universal, in fact it is not a silver bullet. If the estimated use of the design is intended for further use, it must be in a relatively humidier state. We mainly focus on ensuring that the design can still meet the current operation requirements and perform their functions. But if the design collapses (crumbles), that is, radically lost its structural strength, or there is an emphasis on the node to increase its mechanical properties without reference to the base, then the technologies may not be a solution.

3) when considering infrastructure objects when polymer resin is used?

The injection of polymer resins is very easily adapted when it comes to restoring pipe connections, wells and hatches. The reason is that the work can be made both from the inside of the design (with the possibility of access) and from the surface. The polymer is ideal for sealing seams or stabilizing the design. After injection, the polymer is aggressively expanded in all voids, sealing joints against the tributary and infiltration. In addition to the sealing of joints and filling voids, the polymer stabilizes the adjacent soil, providing increased design support and preventing the blurry of the stabilized soil in the future, pushing the design to the surrounding soil.

As mentioned earlier, it is important to emphasize that the state of construction and future requirements for it are an important factor in determining whether the injection of the polymer resin is an applicable repair and recovery option.

4) Is it possible to use the injection of geopolifer to increase the bearing base ability to perceive higher loads?

In general, speaking, the answer is yes, but it significantly depends on how great the weight is, what is the quality state of soils, such as geology and supporting structures.There are several cases when we helped reload the foundations for perception of sharply increased loads, such as silos, cranes, heavy equipment and equipment, as well as reference columns of buildings.In each case, the injection approach was designed specifically in order to use the advantages of the current base and the geological composition of the site.

Not every site is capable of increasing the ability to carry an increasing load. In places with highly plastic soil, an increase in the bearing base ability is limited to the carrier ability of the material itself (up to 10 MPa), since it is not capable of penetrating into the soils of this type on the micro level and cannot create structural integrity by mixing with soils. For the ideal increase in the bearing capacity, the ability of the polymer is to saturate and associate the soil into a continuous structural layer. The injecting solution project can help implement stress dispersion technology to help more evenly distribute the load on the newly fortified ground ground.

Summing up, geopolymer resin Граундтек is an excellent solution for repair and recovery, when design features and financial circumstances allow you to take a flexible, but balanced technical solution.

11 сomments

Baranova Galina· Dec. 27, 2020

It is not clear, applies only when repairing or before construction, you can also deliver to strengthen the soils?

2 thumb_up

replyReply

Post your comment

Aleksandr Efimchik (inzhener GROUNDTEK) Dec. 27, 2020

In both cases, it is possible to apply technologies.The question is only in economic feasibility.Therefore, it is important to study the goals and conditions of the project, to develop a project and evaluation, and then make a decision what method and what money ensures the achievement of the goal

10 thumb_up

Ezhov Pavel· Dec. 28, 2021

But after all, a feasibility study of the project should always be taken into account, so all technology of strengthening in the market and exist, but again I agree in many cases, grained approaches and works, just a situationally need to consider the project from all sides.

10 thumb_up

replyReply

Post your comment

Aleksandr Sinchenko (inzhener GROUNDTEK) Dec. 28, 2021

If everything was done as "put", then no repair and speech would not go ... But our world of people is not perfect and mistakes and their consequences - the usual case of everyday life

10 thumb_up

Kalacheva Alla· Dec. 28, 2020

Is there a guarantee for the restoration of this resin?

2 thumb_up

replyReply

Post your comment

Aleksandr Sinchenko (inzhener GROUNDTEK) Dec. 28, 2020

Of course, depending on the selected solution can reach 60 years

6 thumb_up

Koshelev Jaroslav· Dec. 28, 2021

Taking into account the powerful expansion ability, during sealing pipes, does the polymer fall into the pipeline itself?And is there any likelihood that he will score him completely?

3 thumb_up

replyReply

Post your comment

Aleksandr Efimchik (inzhener GROUNDTEK) Dec. 28, 2021

You are right - such risks exist.For their elimination, examination, data collection, calculation and development of the project, so that these risks are not realized.Be sure to monitor the status of structures as the above-ground and underground

6 thumb_up

Chernyj Boris· Dec. 27, 2021

And when a problem in bunched soils, will help solve the problems of the destruction of structures?

4 thumb_up

replyReply

Post your comment

Aleksej Karpovich (inzhener GROUNDTEK) Dec. 27, 2021

Yes, in the complex with a small additional measure, the problem is solved in the root

7 thumb_up

Sokolov Matvej· Dec. 28, 2020

Is the understanding right with an organic matter with a share of up to 10%, or organic layers with a 90% content of it?

6 thumb_up

replyReply

Post your comment

Aleksej Karpovich (inzhener GROUNDTEK) Dec. 28, 2020

Standard methods work with a organic to 10%.After the threshold of 10% to the development of the draft decision, it is necessary to approach more inlerts with the involvement of engineers of geologists

8 thumb_up

Gurov Dmitrij· Dec. 27, 2021

Do you work with individuals?If a private house has a problem with soils.

10 thumb_up

replyReply

Post your comment

Aleksandr Efimchik (inzhener GROUNDTEK) Dec. 27, 2021

Of course, we work with practically any problems of the grounds and foundations regardless of the form of ownership

9 thumb_up

Kornilov Dmitrij· Dec. 28, 2020

Your material and technology is a panacea from developers errors!

1 thumb_up

replyReply

Post your comment

Aleksandr Efimchik (inzhener GROUNDTEK) Dec. 28, 2020

Not only developers.There are still designers, geologists ... In general, you can generalize - a solution from "building" errors, if one word

5 thumb_up

Gubanova Milana· Dec. 28, 2021

Here everything is of course beautifully painted ... But something is not very observing the polymer strengthening on our construction sites ...

1 thumb_up

replyReply

Post your comment

Aleksandr Efimchik (inzhener GROUNDTEK) Dec. 28, 2021

All because for new construction it is economically not suitable.Concrete or iron-concrete is the cheapest material and is inferior to the place when it becomes unsuitable for the terms of the task that is made out of ...

9 thumb_up

Koshelev Boris· Dec. 28, 2020

And who and how to determine the determination of the problem of the polymer?

7 thumb_up

replyReply

Post your comment

Evgenij Novitskij (inzhener GROUNDTEK) Dec. 28, 2020

Most often these are surveyers or professionals builders after inspection or research

10 thumb_up

Petrovskaja Natalija· Dec. 27, 2021

Can I use your technology in residential apartment buildings?

3 thumb_up

replyReply

Post your comment

Aleksej Karpovich (inzhener GROUNDTEK) Dec. 27, 2021

It is possible in residential multi-unit.But in general, the scope of application applies to any buildings and structures on the natural basis

7 thumb_up

Post your comment